Injection moulding machines are typically designated by their tonnage, which is the pressure in metric tonnes that can be applied to a mould tool, to prevent it from opening when the material is injected under pressure. This can also be represented as locking force in kN. A kilo-newton of force is approximate to that exerted by one-tenth of a kilogramme, so the classification of 1000 kN would equate to a 100-tonne machine.

Larger machines are generally used for larger mould tools, which in turn are typically used to produce plastic components with a larger surface area.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your injection moulding machine requirements.

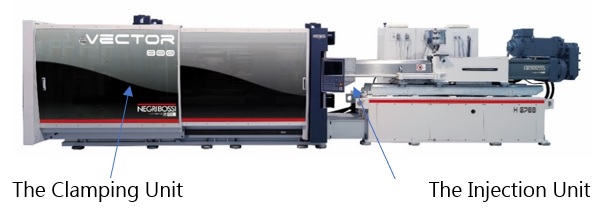

Machines consist of two distinct halves-

On the left are the three main components of a Screw Tip Assembly. The item held in the left hand is the pad, the upper surface of which has an angle that matches that on the back of the check ring. This creates a seal when the ring is pushed back against the pad during material injection.

The purpose of the injection unit is to prepare polymer for injection as well as inject it into the mould tool under considerable pressure, typically quoted in units called ‘bars’ of pressure. The main components are:

As the Screw rotates and material is fed forward, the screw is allowed to be pushed backwards; this is called the ‘screw-back’ or ‘recovery’ phase. This movement is caused by molten material collecting at the front end of the Barrel and applying reverse pressure to the front end of the screw. A check valve is fitted to the front of the Screw, this most commonly being termed a Screw Tip Assembly.

The screw tip is made up of three components – the body, check ring and pad. It is designed so that as material passes to the front of the barrel, it can flow clearly under the check ring and through scalloped channels cut into the nose of the body. When the material is then injected into the mould tool, by a hydraulic or electrically powered ram that pushes the screw forward a precise distance, the ring is forced back against the pad, creating a seal that prevents material from flowing backwards.

This is used to open and close the mould tool, as well as apply the locking force needed to prevent the tool opening when the molten plastic material is injected under pressure. It consists of two metal plates called platens that have fixing points to allow each half of the tooling to be mounted. One of these platens is static (the fixed platen), and the other (the moving platen) reciprocates.

This fixed platen is adjacent to the output end of the injection unit and has a large diameter, centralised aperture at its centre. The material injection nozzle of the injection unit can pass through this aperture and come into direct contact with the material entry point (sprue bush) on the rear face of the mould tool.

Behind the fixed platen, a component ejection system is mounted. This has linkages that pass through holes in the fixed platen and couple to a moving plate within the mould tool. In turn, this pushes rods called ejector pins backwards and forwards, pushing a cooled moulding off the tool. The component will then either free fall or be collected by an operator or robot.

Servo-hydraulic machines are the most common form of injection moulding machine. All main machine elements are powered using hydraulic pressure, including platen movement, screw rotation, ejector system movement and the high-pressure injection of molten material.

The machine will have one or more hydraulic pumps, but unlike in the case of older machines, the pumps are powered by an electric servo motor. This motor has variable speed control, meaning that only the required amount of hydraulic energy is generated and expended. For example, if a moulded product requires a long cooling phase, the machines pump will be virtually inactive during this phase of the moulding cycle.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your servo-hyraulic moulding machine requirements.

As the name implies, an all-electric injection moulding machine uses electric actuators to carry out all primary machine movements. This can involve the use of servo motors to apply rotary motion directly, but most commonly utilises ball screws to convert rotary into linear movement.

If a hydraulic circuit is required to provide core-pulling, then a servo powered self-contained power-pack can be integrated with the machine.

All-Electric technology is more energy-efficient than hydraulic technology, but machines also demonstrate higher levels of cleanliness, precision and repeatability. These attributes mean that they are frequently employed within the medical and pharmaceutical sectors.

The capital cost of an all-electric machine is generally higher than for other technologies.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your all-electric moulding machine requirements.

Hybrid drive machines use a combination of hydraulic and electric actuators. For example, screw rotation and clamp movement may use electric drives to reduce energy consumption. By utilising hydraulic power for other machine movements, machine costs can be lower than for an equivalent size all-electric machine.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your hybrid drive machine requirements.

Unlike a standard horizontal injection moulding machine which has a single injection unit, a multi-material machine (sometimes called twin-shot, two-shot or 2K machines) has two or more injection units. Each additional injection unit can supply a separate material grade or colour of material into an injection mould tool.

Injection units can be mounted in several configurations, e.g. vertically, horizontally or ‘piggy-back’, where a second unit is positioned directly above the main unit.

Typical applications might be the addition of a soft feel material such as TPE to a paintbrush handle. In most cases, the primary injection unit will have a much higher shot weight than any additional units.

Multi-Shot moulds are very complicated and are often more expensive than the machinery. Robots are generally utilised to manipulate the product within the mould to allow for the second shot to be injected. The robot head then rotates and removes the completed two shot component. For multi-impression, multi-shot applications, the use of a rotary table or platen is often utilised to improve the productivity.

Visit here to contact the leading UK companies that can provide you with advice and quotes for Rotary Platens.

If budget is limited, standard injection moulding machines can be converted to multi-shot by adding a bolt-on injection unit. There are specialist companies in the market that supply these independent injection units for use in these applications.

Visit here to contact the leading UK companies that can provide you with advice and quotes for a Secondary Injection Unit.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your multi-material machine requirements.

As the name implies, vertical injection moulding machines have a clamping unit that opens vertically. The injection unit is generally mounted above the clamping unit, making the foot-print’ of the machine much smaller than that of a horizontal machine.

This design is well suited to processes where an operator or robot is used to place additional items into a tool. For example, with insert moulding, a non-plastic component is inserted into the mould tool. The tool is closed and plastic moulded around a proportion of the added item. Examples would be moulding the grip handle around a screwdriver steel shaft or incorporating copper electrical connections into an item.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your vertical moulding machine requirements.

LSR machines combine a liquid base material with a catalyst by drawing these materials from storage containers and mixing them prior to injection into a mould.

A chemical reaction causes the material to set within the mould tool. These machines are significantly different from a standard injection moulding machine and cannot process other material types. They are, however, far more accurate than rubber moulding equipment and there is no or little flashing of components.

Typical components would be baby bottle teats and swimming goggles.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your LSR moulding machine requirements.

Packaging machines are designed for manufacturing thin-walled containers or products. Cycle times can be very fast, so machines have up-rated clamping units to cope with extended production levels with high opening and closing speeds.

Common upgrades can include oversized tie bars and platen guidance and support systems, as well as steel rather than cast iron platens.

Injection units also tend to have longer than typical L/D ratios, to cope with high levels of material throughput. Where wall thickness makes filling the mould difficult, the injection unit may be fitted with accumulators. These devices use an inert gas within a sealed vessel that is compressed by pumping oil into the top of the vessel during part of the moulding cycle. This stored energy is then released during the material injection phase, a servo valve diverting the oil into the rear of the hydraulic injection cylinder. This results in very high injection speeds, which helps to fill the mould.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your packaging moulding machine requirements.

Micro moulding machines are designed to produce components where accuracy levels cannot be achieved using standard equipment.

As well as being smaller (size and tonnage) than typical, these machines also use technologies such as all-electric drives and specialised injection units. For example, a small diameter plasticising screw can be used to deposit a dosed amount of material into a plunger type injection unit. This unit has no check ring and can inject a very precise amount of material into a mould.

Visit here to contact the leading UK companies that can provide you with advice and quotes for your micro injection moulding machine requirements.