In this blog, Telsonic UK’s Martin Frost outlines the principles and benefits of the Cut’n’Seal process which, due to its flexible nature, is leading a growing number of manufacturers to incorporate the technology within their production systems.

The Cut’n’Seal process uses ultrasonic energy to cut or punch out a range of thermoplastic and synthetic type materials while sealing the edges. If also required, the process can join the individual components to a secondary item. Capable of cutting and joining a range of substrates, the Cut’n’Seal ultrasonic process is a mature, well-established technology already used for a number of applications on filtration, garment, medical, wound care and healthcare products.

There are a large number of items manufactured from multiple layers where it is essential that the finished item has no frayed edges, loose threads, or does not de-laminate in use.

In certain cases, in addition to the aesthetics and integrity of the product, there are also instances where the ultra-smooth edge produced is an essential attribute for items that will come into close or constant contact with the skin.

The Cut’n’Seal process is capable of meeting all of these requirements, which is why manufacturers are adopting the technology across multiple industry sectors.

Telsonic’s Cut’n’Seal process has a proven track record on a wide range of applications and across multiple sectors

Telsonic UK’s Martin Frost explains: “Examples of where the Cut’n’Seal process has proven to be indispensable include the high volume manufacture of labels, wound care products, feminine hygiene products and filter pads of varying shapes and sizes, such as those used within respiratory support machines for patients suffering from sleep apnoea. In addition, the flexibility of the process means that it can be incorporated into a wide range of manufacturing technologies.”

Typical Reel / Reel-Fed In-Line set up – material indexes through the Cut’n’Seal station

For high volume products, the typical configuration would be a reel-fed indexing system where pre-laminated multi-layer material is passed between the sonotrode(s) and anvil(s). The individual pads, which have been both cut and sealed, are then pushed through the anvil by dedicated pneumatically operated plunger mechanisms and collected in tote boxes, ready for packaging. The skeletol waste of the original material is then fed onto a separate reel on the output side of the machine. Depending upon product design and reel width, this configuration allows for either single or multiple products to be produced each cycle.

Changeover between product types or shapes is achieved by simply changing over the sonotrodes and anvils, and if required, adjusting the position and/or pitch of the tooling. Telsonic’s Cut’n’Seal technology can achieve cut cycles of between 140/170 ms, representing a very small part of a machine’s overall process and index time.

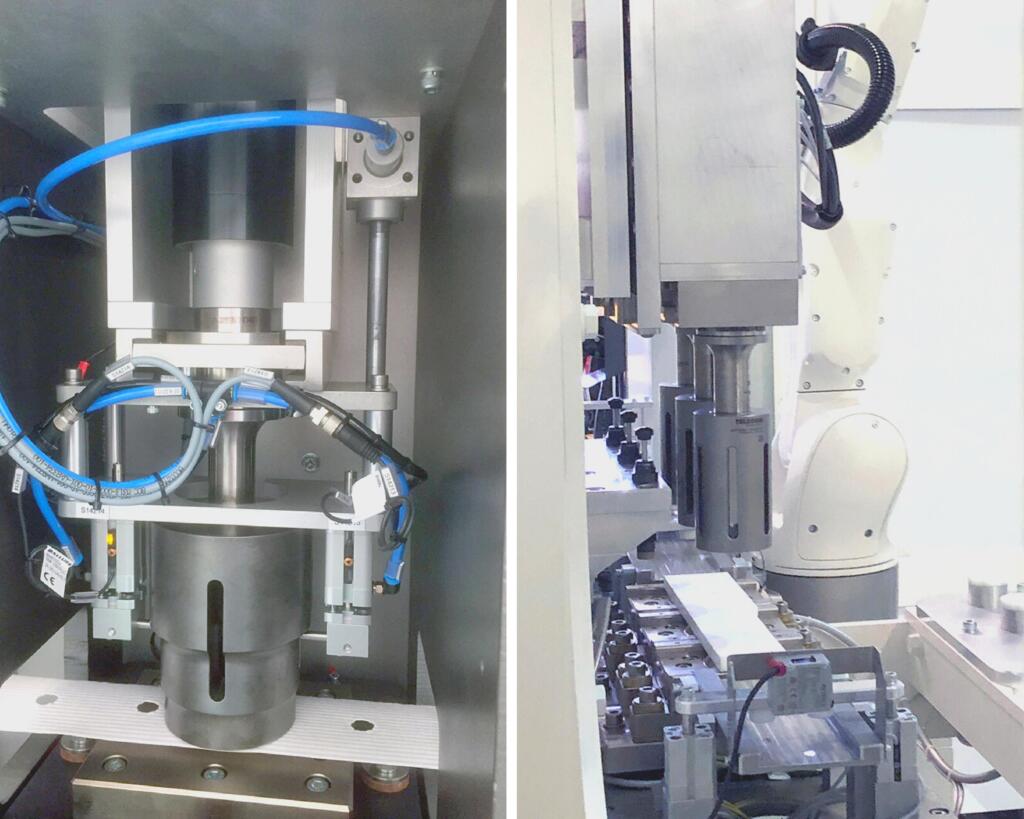

The Cut’n’Seal process is also easily integrated into systems where robots are being used. For example, in this application, the robot removes the cut and sealed pads from the anvils and loads them into intermediate trays prior to presentation into filter housings further upstream in the manufacturing process.

A robot picks ultrasonic Cut’n’Seal Pads for transfer to upstream

assembly into filter housings

Another Cut’n’Seal configuration often employed is that of twin-headed systems but offset sonotrodes and anvils. This utilises wider web substrates where two smaller pads can be produced in a tandem cycle whilst optimising material usage. In a configuration such as this, the reel-fed material is typically between 100mm and 150mm wide and between 100 and 150 gsm in thickness. The typical throughput for a system such as this would be a total of 60 pads per minute, dependent upon material type and thickness.

The rapid rise in the demand for surgical type face masks, initiated by the Covid-19 pandemic, brought with it a significant increase in the number of UK companies diverting their resources to manufacturing these products using automated systems. Once again, Telsonics’ ultrasonic technology plays a key role, and the Cut’n’Seal process, in particular, is used to produce cut and formed mask types such as K95/N95 and FFP2/FFP3 variants.

Dual, offset sonotrodes and anvils maximise productivity whilst optimising material usage

Martin Frost concludes: “The quality, consistency and short cycle times of the Cut’n’Seal process, combined with the ability to easily configure and integrate the technology to suit individual applications, are just some of the key drivers behind the increasing uptake of Cut’n’Seal as the process of choice for a growing number of manufacturers. In addition, developments in wound care technology with new materials, new feminine hygiene products, plus the demand for increased production of PPE as a result of the ongoing pandemic have together opened up a wide range of new applications for this process, which also adds value by delivering a superior finished product.”

Telsonic UK offers a comprehensive range of ultrasonic modules and systems for a variety of plastic welding, cutting, sealing, Cut’n’Seal, food cutting, metal welding, packaging, sieving, and cleaning applications within a wide range of industries.