In this blog, Process Parameters, a UK-based manufacturer of Industrial Temperature Sensors, discusses how an Optris Thermal Imaging Camera can become part of your process measurement and control.

When thinking about infrared thermal imaging cameras, there tends to be an immediate thought of either security cameras with night vision systems or handheld devices commonly used in applications such as building thermography and spot-checking electrical panels. Of course, these are massive industries and many products fill these needs.

When considering industrial applications such as those found in the plastics industry, there is less knowledge of the capabilities of the technology. Many producers will utilise handheld infrared thermometers or cameras for spot-checking equipment and machines, but these are heavily reliant on an operator continuously viewing the image and interpreting the results correctly whilst understanding the limitations of such a device. For high-speed applications, this is impossible.

Now imagine if you could integrate a thermal imaging camera into your existing process measurement and control systems at a surprisingly low cost. Imagine being able to have a complete thermal view of each and every part you produce and automatically provide feedback to your control system to improve quality and yield. Rather than work in the dark by monitoring temperature at a few points with thermocouples, shed light on what is happening within your process and drive consistency and uniformity in your temperature control.

Optris Thermal Imaging Cameras are designed for precisely this type of application. The miniaturised rugged designs are intended for mounting on industrial machines to provide continuous monitoring of a given process. This could be injection moulding, extrusion, vacuum forming, or blown film processing.

There are a few key design features of the Optris camera range that lend themselves to this type of use:

- USB or Ethernet connection to a Windows PC allows the cameras to be very small and low cost. Mounting the cameras onto machines is easy as they take up very little space and are perfectly capable of handling arduous environments.

- High-speed frame rates of up to 120Hz allow the monitoring of extremely high-speed applications. With response times of approximately 12 milliseconds, Process Parameters can capture fast moving processes, for example, parts being ejected from mould tools.

- High-resolution images allow the temperature measurement of very small objects or parts, often impossible to achieve and often the cause of many moulding quality issues (too hot, too cold, short shot, etc.).

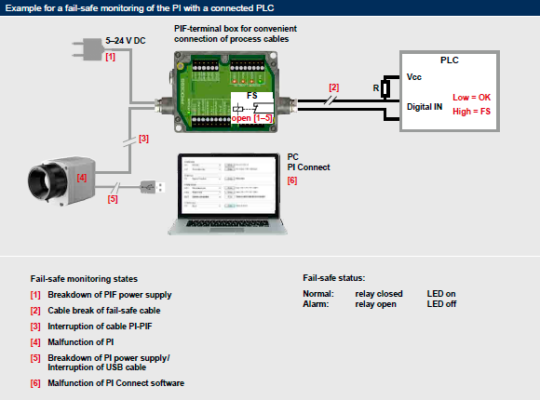

The key feature of all Optris Thermal Imaging Cameras that makes integration so easy is that they include a “Process Interface.” This interface is a direct connection between the camera and your process control system and can be used as a direct replacement for existing sensors such as thermocouples.

The process interface is easily configured to provide a variety of inputs and outputs. For example, the interface can provide a direct alarm output should a set of temperature conditions not be met. Alternatively, it can provide an industry-standard 4-20mA output to your process control equipment.

You can also provide the camera with inputs from external sensors to tell the camera when to take measurements.

It is possible to provide multiple outputs from the camera using Process Parameters’ optional Industrial Process Interface which will provide up to three outputs. Each output can be configured to monitor an individual area on the screen, called measuring areas in Process Parameters software. Each of these can be configured to a different area on the component being manufactured.

Process Parameters is the UK distributor for Optris, a German manufacturer of infrared thermometers and thermal imaging cameras. Process Parameters has more than ten years’ experience in this field and can help you achieve the best performance from this type of product.

Get in touch with Process Parameters using the contact details below to go through your application and find out if Thermal Imaging can improve your process.