Guest Blog by Nick Parker of DB Automation

As a company specialising in high speed part removal from injection moulding machines, we are often asked to justify the price differential between our standard Cartesian (three-axis or ‘beam’) robots and our side entry models. An installation of our flagship CFR (Compact Flexible Robot) side entry unit costs around double that of a Cartesian solution, so the aim of this blog is to help you decide which is right for your particular project….

Fast cycling?

As a starting point, we need to consider the definition of a ‘fast cycling application’. When costing a new moulding project that is ‘high volume, low margin’ in nature, a consistent cycle time is everything. The target cycle time has to be met, day in day out, otherwise it is very easy to fall behind production requirements and to run at a loss. Packaging applications are a good example of this.

So how fast is fast?

‘Semi-packaging’ type production, often being limited by thicker wall sections, may involve target cycle times of around ten seconds or so. A good Toolmaker can work out injection and cooling times for you, but you still need to consider tool opening/closing time and product de-mould (take-out) time.

True high speed packaging applications can require cycle times as low as 5 seconds, this again being the total time including ‘mould delay’, i.e. the time that the process is delayed due to the activity of the robot.

The vital figures

A Cartesian robot will struggle to get below 1.0 to 1.2 seconds for take-out time, and a bulky wrist also means the tool needs to open much further with a Cartesian robot. This will extend the cycle further, as open/close stroke is dead time.

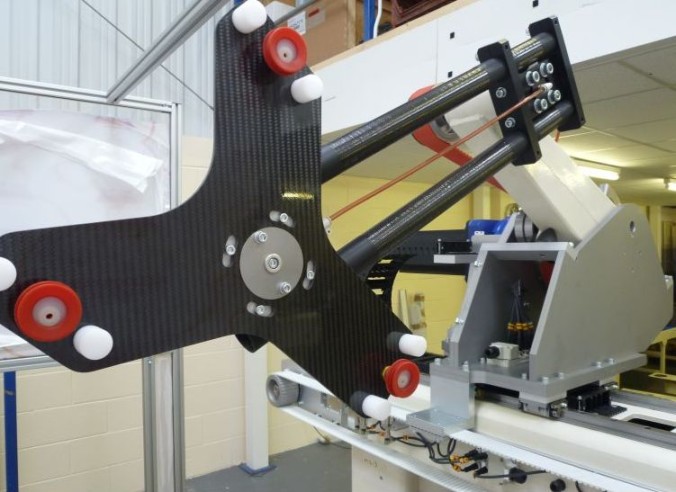

By comparison, even standard side entry beam robots can achieve a mould delay (take-out) time of down to 0.5 seconds, this falling to as low as 0.3 seconds in the case of the CFR model.

Where slim products with little depth are moulded, side entry units are perfect as virtually no strip stroke is required, and the tool opening can be minimised. With our CFR unit, it is still possible to handle ‘deeper’ products and achieve very fast de-mould times. By tracking the opening of the tool, the robot is configured so that it follows the moving face of the tool as it opens and collects the product during the move and then exits the mould with a very minimal delay.

All of these combined factors mean that cycle times typically as low as 5 seconds can be easily achieved with a side entry robot, whereas a Cartesian unit will struggle to get below 10 seconds for comparable strokes. It should also be mentioned that the side entry models are designed for continuous high speed use, unlike a standard ‘off the shelf’ Cartesian model that would be operating at the upper limits of its capabilities when running at these cycle times.

Other factors to consider

Once you have established that a project requires a true packaging specification mould tool, and that a side entry robot is needed to achieve your target cycle time, what else should you consider?

- The machine – if your injection moulding machine has insufficient plasticising capacity, and/or slow opening and closing speeds, this will prevent you from achieving your target cycle time. You will usually also need a high injection speed, possibly through the use of accumulators.

- Down-time – in reality, machines and mould tools need some degree of maintenance, so you should allow for this.

- Post mould product handling. When such a high volume of product is created good provision needs to be allowed for post moulding operations, such as bagging, carton packing, collating etc. Along with this a buffer consideration should be made to allow the system to continue to mould if the downstream operator functions is interrupted for breaks etc.

- High volume part production requires high stock levels of raw material and the right balance of storage space verses shipment.

Other side entry applications & considerations

Side entry robots are more suited to IML applications than Cartesian models, as movements of the foil are kept to a minimum, hence disturbance on the mandrel is kept to a minimum.

Where head room is an issue, Cartesian solutions often struggle whereas side entry units do not. Six axis robots also tackle this issue, but again, they cannot achieve such high take-out speeds and their design means even greater mould opening strokes are needed.

Where a stack mould tool is required, the clear leader in application suitability is the side entry beam robot. It is fair to argue that there are now Cartesian solutions for stack moulds, but their suitability is still playing catch-up to the side entry solution, which with a double arm easily copes with a stack tool.

Still not sure?

If you would like to discuss a particular application, our knowledgeable team are well equipped to help you find the best solution possible. www.db-automation.co.uk

Acquire quotes for Robots & Automation from DB Automation and other UK industry leaders here.