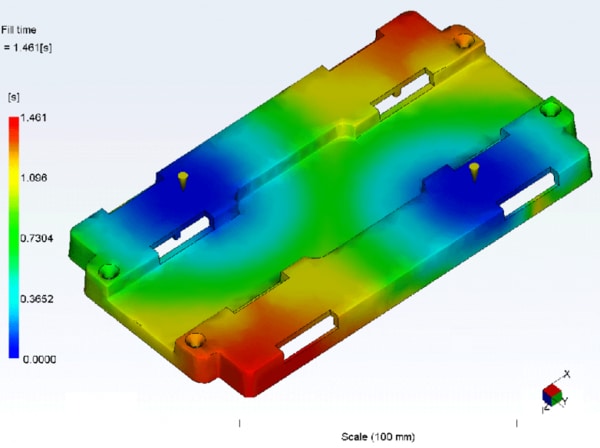

Moldflow software allows the flow of plastic inside a mould tool during the injection moulding process to be analysed. The 3D CAD data generated during the design process can be used directly to determine the manufacturability of the part.

Material, tool and moulding parameters are assigned to the geometry and the analysis run. The results generated are numerous and detailed and include full-time pressure, temperature, weld lines, areas of poor flow and sink marks. More complex analysis can show warpage, areas of distortion, fibre flow and shrinkage.

When should we use moldflow analysis?

A mould with a more complex shape will likely benefit from moldflow analysis because the flow is less predictable than with a simpler shape. The current trend is to make products lighter & thinner to save material cost, but this makes moulding quality parts more difficult. The ability to optimise the gate location can prove essential for some parts with more complicated geometries.

Changes to the part design and also the tool design can be investigated and confirmed based on the moldflow output and potential quality issues in the part such as deep under cuts, or inadequate draft angles can then be altered immediately to address these issues with little time and cost.

The benefits of using moldflow analysis

The advantages of moldflow are many, and the ability to see how a manufacturing process will work before financial outlay has been committed to tooling is priceless.

At Plunkett Associates we regularly use moldflow analysis so that new part designs can be analysed immediately for manufacturability. This includes not just the ability to mould a part, but also the quality of the resulting part, both physically and aesthetically.

In the past, there was a risk that flaws in part designs would not be noticed until a mould tool was made. Creating a virtual version through moldflow analysis, means multiple trials can be avoided, and time and money saved, as changes in part and mould design at this stage would be far more expensive.

If you think analysis would help your product development, give us a call, we will be glad to assist.