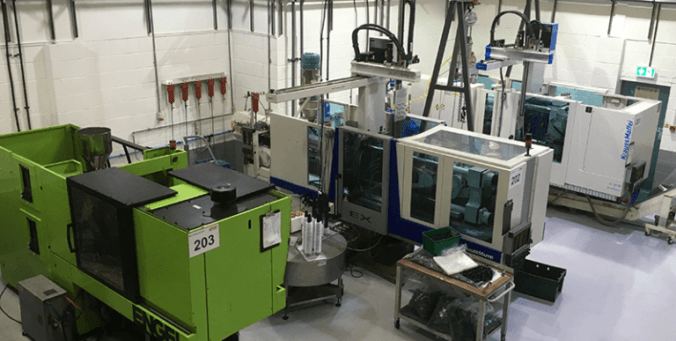

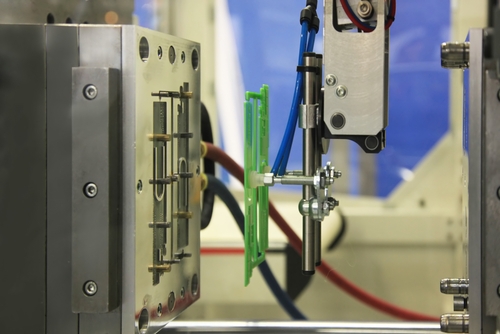

Automation systems for plastic moulding are transforming production processes by enhancing efficiency, improving precision and consistency, and reducing costs. These automation systems, or automation cells, use advanced machinery and robotics to automate tasks once done manually, enabling continuous, high-volume production.

Choosing the right supplier for your automation cell or system is critical for manufacturers in the plastics industry aiming to improve their production capabilities and efficiency. This article highlights the top 4 suppliers of automation systems making a significant impact in the plastic moulding sector.