In this blog, Davis-Standard, a leader in high-performance converting and extrusion systems, has summarised thirteen common pellet quality issues with photo examples, defect names, possible causes and troubleshooting steps for correction.

Having issues with your pellets? The good news is there are some troubleshooting techniques to yield more uniform pellets.

Under normal processing conditions and with properly designed equipment, underwater pelletising should yield pellets uniform in size, shape, weight, and other desired characteristics for subsequent processing or aesthetics. To ensure consistency, it’s important to identify common issues that lead to pellet defects during start-up, including worn pelletising components and incorrect operating conditions. In most cases, pellet defects have multiple causes.

Addressing one variable at a time and allowing time between adjustments will help you determine the full effect of each change before making additional modifications.

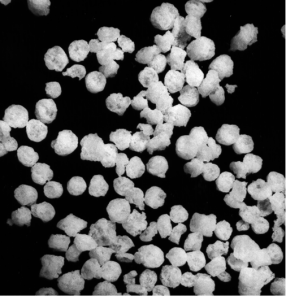

Issue 1: Agglomeration and Large Clusters

Cause:

- The product is too hot

- Quench water is too hot

- Low quench water flow

- The product is inherently tacky

- Die holes are too close

Troubleshooting:

- Lower the product temperature

- Lower the water temperature

- Check water rate

- Check for proper surfactant levels, if applicable

- Make knife adjustment

Issue 2: Fines and Angel Hair

Cause:

- Chipped or cracked orifice tips

- Die holes are partially blocked

- The shaft is not aligned properly

- Knife tracking issues

Troubleshooting:

- Make knife-to-die adjustment

- Plug chipped holes

- Purge die and check flow uniformity

- Check ID/OD knife coverage on orifice holes

- Realign pelletiser

- Refurbish die plate

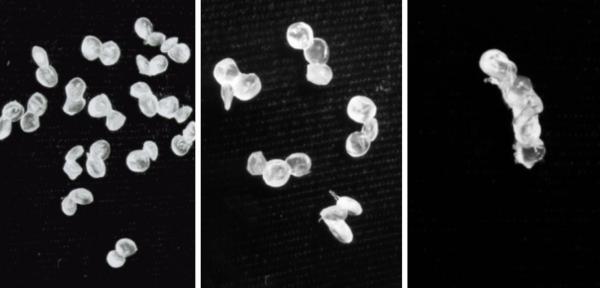

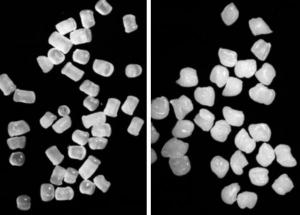

Issue 3: Twins, Triplets and Chains

Cause:

- The product is too hot

- Quench water is too hot

- Low quench water flow

- Knife speed is too high

- The product is inherently tacky

- Die holes are too close

Troubleshooting:

- Lower product temperature

- Lower temperature

- Check water flow rate

- Reduce knife speed

Issue 4: Dog bones and Dumbbells

Cause:

- Low viscosity or high MI product

- Elastic/stretchy product

- Blades are worn beyond the limit

Troubleshooting:

- Make knife clearance adjustment

- Lower quench water temperature

- Ensure the blades’ leading edges are sharp

- Replace knife hub

Issue 5: Tails

Cause:

- Chipped or cracked orifice tips

- The knife-to-die gap is too large

- Die surface is irregular

- The shaft is not aligned properly

- Knife tracking issues

Troubleshooting:

- Plug chipped holes

- Make knife adjustment

- Check ID/OD knife coverage on orifice holes

- Realign pelletiser

- Replace and refurbish die plate

Issue 6: Longs and Elbows

Cause:

- Knife speed is too slow

- The extrusion rate is too high

- Frozen die holes

- Low melt temperature

- Too few knives on the knife hub

Troubleshooting:

- Complete pellet efficiency calculation

- Increase the knife speed

- Reduce the extrusion rate

- Increase the die temperature

- Increase the water temperature

- Restart the pelletiser

- Increase the number of knives

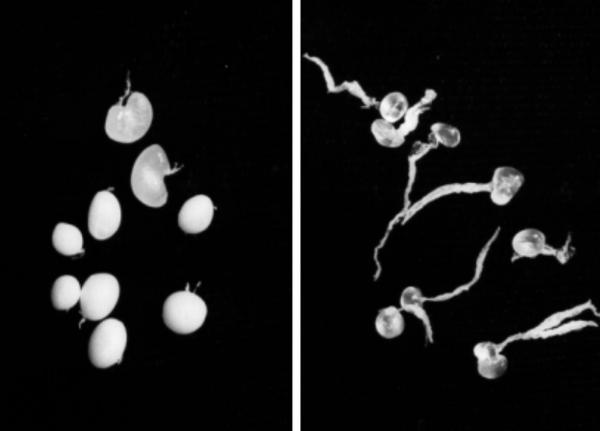

Issue 7: Internal Voids

Cause:

- Moisture in the polymer entering pelletiser

- Entrained gas or volatiles in polymer

- Quench rate is too fast

Troubleshooting:

- Ensure the polymer is dry

- De-gas polymer upstream of pelletiser

- Strip polymer solvents

- Increase quench water temperature

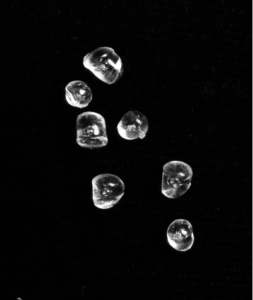

Issue 8: Dimples

Cause:

- Shrinkage due to fast quenching

Troubleshooting:

- Increase quench water temperature

Issue 9: Dust

Cause:

- Product is friable or brittle in solid-state

Troubleshooting:

- Slow centrifugal dryer speed; no more than 10%

Issue 10: Surface or Melt Fracture

Cause:

- The extrusion rate is too high

- High die-hole shear rate

- The product is too viscous

- Frozen die holes

- Orifice hole final land is scored

Troubleshooting:

- Reduce the extrusion rate

- Increase product temperature

- Use a larger hole diameter

- Use a shorter orifice hole final land length

- Increase die plate internal temperature

- Smooth final land surface

Issue 11: Trash or Shavings

Cause:

- The knife-to-die gap is too large

- Infrequent knife adjustment

- Die face has a build-up of smeared product

- Blades are not ground properly

- Die surface is worn irregularly

- Product is inherently stringy

Troubleshooting:

- Make knife adjustment

- Blades are worn beyond the limit

- Ensure the blades’ leading edges are sharp

- Replace the knife hub

- Refurbish the die plate

Issue 12: Popcorn

Cause:

- Moisture in polymer entering pelletiser

- Entrained gas or volatiles in polymer

- Quench rate is too fast

Troubleshooting:

- Ensure the polymer is dry

- De-gas polymer upstream of pelletiser

- Strip polymer solvents

- Increase quench water temperature

Issue 13: Non-Uniform Pellets in Length, Size, or Shape

Cause:

- Temperature or viscosity change in product

- Die plate segments are not evenly heated

- Die plate heating manifold inlet/outlet design

Troubleshooting:

- Add static or another mixer

- Check condensate traps or other heating media restrictions at each die plate segment

- Refurbish die if insulation is lost

Finally, use recommended calculations to determine if your die plate orifice holes are open before making other adjustments. This will ensure you are not adjusting your underwater pelletiser to produce optimum pellets at a sub-optimum rate.

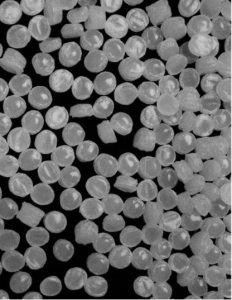

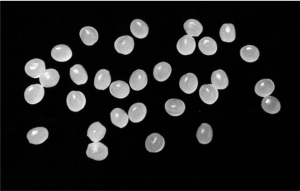

Pellets uniform in shape and size

If you need assistance in calculating the percentage of open holes, get in touch with the team using the contact details below.

This guide was provided by the Davis-Standard Connect Blog team. For more blog entries, visit the DS Blog Archive.

Davis-Standard

+44 (0) 1384 471930

Website

Email